Environmental Monitoring

What is Environmental Monitoring?

Environmental Monitoring is defined as the observation of the presence of harmful factors such as toxins, bacteria, chemicals and other pollutants in a specific location.

In other words Environmental monitoring describes the processes and activities that need to take place, to characterize and monitor the quality of the environment. Environmental Monitoring is a surveillance system for microbiological control of clean rooms and other controlled environments. It is a process which provides monitoring, testing and feedback to the microbiological quality levels in aseptic environments.

Environmental monitoring in microbiological testing plays a critical role in ensuring the safety of patients and the efficacy of drugs and biologics by preventing their contamination with microbes. Microbiological testing alone does not provide complete or absolute assurance of absence of microbial contamination but helps to ease the process of investigation of microbes which are present in laboratories or manufacturing units.

Basic Environmental Monitoring Tests in pharmaceuticals

Active sampling - Air sampling is a method used to find out what airborne contaminants are present in your environment. Air is collected by using various methods and then, it is tested for the presence and concentration of hazardous substances and microorganisms.

Passive Sampling - Passive air sampling basically involves leaving settle plates or contact plates exposed to the air for a certain period of time to collect microbes that may settle onto the surfaces of the plates.

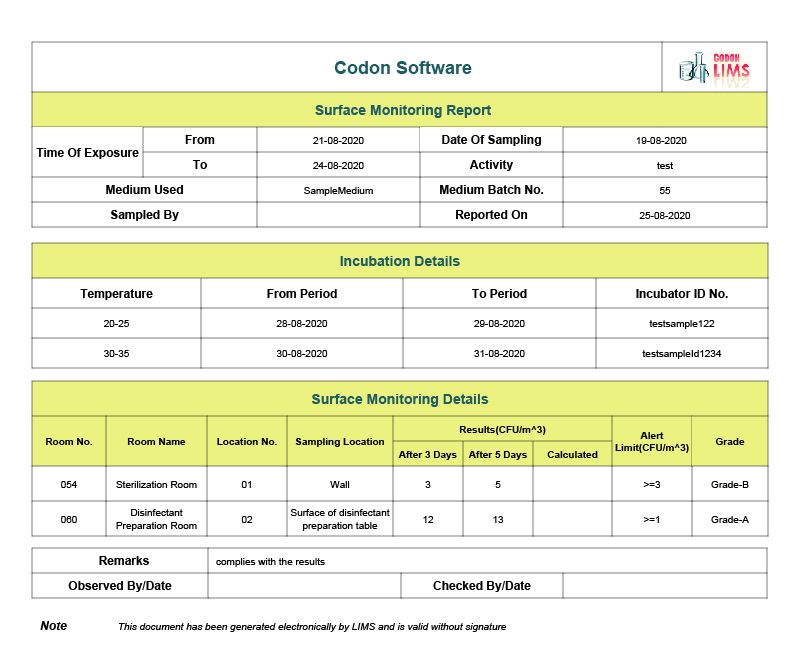

Surface monitoring - Surface Monitoring is a method used to find out what airborne contaminants are present in your environment. The samples are collected from the surface of the lids, which are placed for some period of time at a certain environment and those lids will be taken for testing.

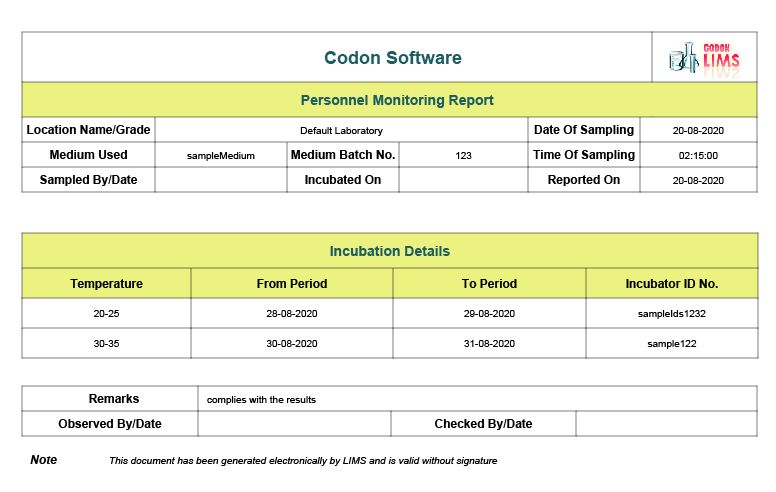

Personnel Monitoring - Personnel Monitoring is a method used to find out the microbes from the person who exposed or worked any radioactive conditions for a certain period of time.

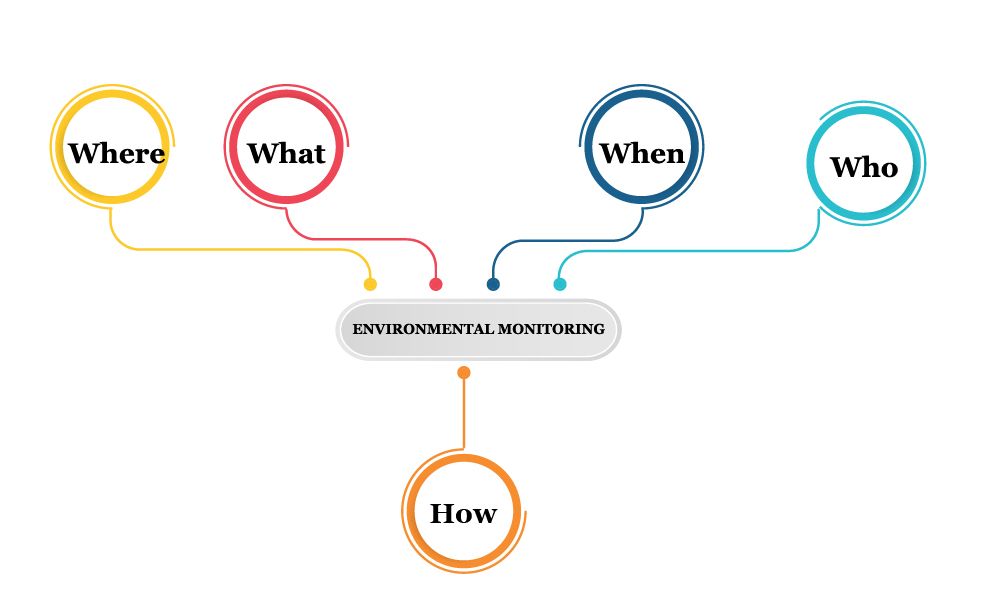

Workflow of Environmental Monitoring

Where: Environmental Monitoring will be carried in manufacturing areas, like pharmaceuticals, Cosmetics, Researching Laboratories and desired locations.

When: Environmental Monitoring will be done based on the manufacturing areas rules and regulations. For example, if it is a Battery manufacturing unit, then every week twice the EM will be done to check the Lead levels of the environment. Likewise the EM will vary from Location to location and Weather Conditions too.

Personnel monitoring will be held when the operator leaves the process area. This type of monitoring will be done very frequently.

What: In Environmental Monitoring, the environmental properties like, soil, air, water will be tested for their environmental conditions, getting the accuracy of the particular area will help to provide sterile and suitable conditions for running the production smoothly.

Who: The Well trained Microbiologist trainers will perform the End to End Environmental monitoring tests. These trainers must and should get trained on the instruments which are going to be used in performing the environmental monitoring tests because, the results are very crucial for production.

How: As per the current practices, there are SOPs and ISO documents which will guide and define the procedure to follow and perform the Environmental Monitoring. The trained Microbiologist will perform the Monitoring process accordingly.

Some of the Guidelines are listed below for reference

- The U.S. General Service Administration's standards (known as FS209E) Global clean room classifications and standards were adopted by the International Standards Organization (ISO).

- ISO-14644 The first Federal Standard 209 published in 1963 Revised in 1966 (209A), 1973 (B), 1987 (C), 1988 (D) and 1992 (E), and withdrawn in 2001.

- By law, Federal Standard 209E can be superseded by new international standards. It is expected that 209E will be used in some industries over the next few years, but that eventually it will be replaced internationally by ISO 14644.

CodonLIMS provides platform to capture the data of Environmental Monitoring parameters across multiple locations of a plant. By using the data collected based on predefined tests, CodonLIMS can generate reports to help understand on-ground situation and take precautions accordingly for smooth functioning of production facilities. Two typical report are enclosed for reference.