Automotive Component Testing with LIMS

What is it?

Across automotive supply chain, validating the physical behaviour and performance of automotive components is key to safety of customers and will also improve driving experience.

Measuring various parameters like compression, resistance, lamps, pedal se sensors, tension, strength etc. on individual components and sub assemblies in accordance to international standards is necessary before automobiles can be released to outlets for sale.

Why is it necessary?

Quality control is an important factor for Original Equipment Manufacturers (OEMs) of Automobiles require the best in quality components through the supply chain. High quality is needed to meet customer requirements and also to avoid costly recalls. Each and every automotive material and component should be going through extremely thorough and careful testing to meet industry and legal requirements. Usually automotive component manufacturers are ISO 17025 accredited.

How LIMS helps during automotive testing?

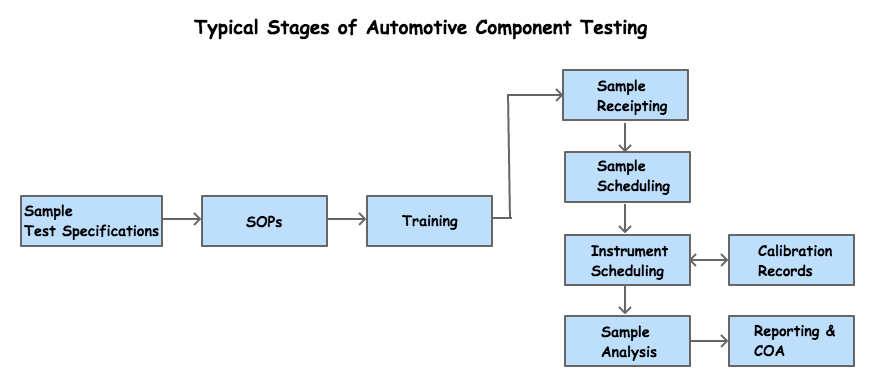

1. Sample Test Specifications

- Parameters that need to be tested

- Characteristics of parametric values

- Instruments needed for testing

2. Standard Operating Procedures

- Skills needed for testing

- Process involved

- Make SOP available during testing

3. Training Needs

- Training matrix of Test Analysts

- Compliance with industry Standards

- Evaluate training needs regularly

4. Sample Receipting

- Receive Samples from various teams

- Assign Sample ID and automate barcode generation

- Alert appropriate Managers of the receipt

5. Sample Scheduling

- Calendar display of Sample analyses

- Allow priority based changes

6. Instrument Scheduling

- Calendar display of instrument usage

- Avoids conflicts

6a. Instrument Calibrations

- Maintains complete calibration records

- Alerts on pending calibrations

- Make available only calibrated instruments

7. Sample Analysis

- Collect data from analysis based on specifications

- Provide immediate alerts if parameter values are OutOfSpecification

- Alert management for approval samples analyzed

8. Reporting & Certificate of Analysis

- Immediate access to management reports

- CoA for all samples

- Historical records availability for future

Takeaways

- Improved 360 degree view of sample flows - receipting to analysis to results

- Compliance with regulations

- Streamlined flow of processes

- Objective data for management

- Objective data for customers on sample analysis - Internal or External

Please reach out to support@codonlims.com for any specific questions on how CodonLIMS can become a valuable cog in automotive component quality analysis flow.